Aerosol Pesticide Sprayer Filling Solution

The usage of Pesticide Aerosol

Pesticide aerosol, by spraying, can quickly kill mosquitoes, flies, cockroaches and other pests. It is one of the indispensable daily necessities in our life. With good killing effect, easy carriage & storage, rapid result, accuracy and other unique advantages, it has been developed rapidly. Aerosol refers to the preparation (canned meterial) which is sprayed out in the form of mist, and the canned meterial and propellant agent are packed together in a pressure tank with a valve. The micro fog particles ejected are called aerosols.

Taking China as an example, as early as 1992, the annual production of pesticide aerosol reached 50 million cans, which has a very broad market. In Southeast Asian countries with hot climate and more mosquitoes, such as Pakistan, Thailand, Malaysia, Indonesia and other regions, the demand for pesticide aerosols is also very high.

How to produce pesticide aerosol?

With the rapid development of pesticide aerosols, more and more attention has been paid to the quality of products. How to evaluate the quality of pesticide aerosol? Most producers, distributors and users often simply evaluate the quality of products by their biological effects, but ignore many other important factors that affect the quality of products.

As we all know, aerosol technology is a multi-disciplinary comprehensive technology. From the perspective of the integrity of aerosol products, it is not a simple addition of containers, valves, ejectors and insecticidal active ingredients, but also involves the use effect, safety and economy. It should also comply with the World Health Organization (who) Regulations on pesticide toxicity. Therefore, the quality of pesticide aerosol products should be comprehensively evaluated from three aspects: physical and chemical properties, biological effects and safety.

Filling equipment of pesticide aerosol

Since pesticide aerosols are usually corrosive chemicals, the contents of the aerosols will corrode the tank, sealing valve, and internal surface. The corrosion often occurs inside the tank, which shortens the storage resistance of the container and increases the leakage of the container. Especially in summer, due to the influence of ambient temperature, the corrosion is intensified.

In view of this situation, we usually use bag on valve technique to fill pesticide aerosol. HDC provides complete bag on valve filling equipment, mainly including can ranging machine, liquid filling machine, valve inserting machine, sealing and propellant gas filling machine, capping presser and etc.

Aerosol Pesticide Sprayer Filling Solution

To help our customers set up pesticide aerosol business, we offer 1vs1 technician service including formula suggestions, layout design, equipment using guidance. Some functions can be adjusted on demand.

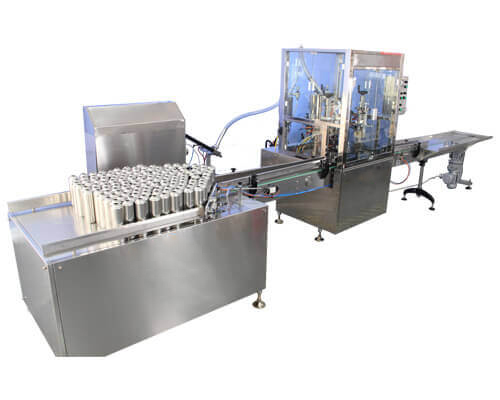

120A Small Automatic Aerosol Filling Machine for Aerosol Pesticide Sprayer Production

There are two sets of main function filling machines in this HDC 120A Aerosol Filling Machine series. It's a basic aerosol filling line that will accomplish simple aerosol filling and sealing. This aerosol assembly line is more popular to the beginner in aerosol production area.

For specific machines, there are two liquid filling machines, valve correcting machines, sealing and gas filling machines. And the filling is organized in a rotary table.

HDC 120A Aerosol Filling Machines are CE verified with branded core mechinery embedded. We use Siemens PLC control and Schneider low voltage component to ensure better stablity and durablity.

Although it's a basic solution to offer backbone aerosol filling functions, we can make it more powerful and flexible by adding bottle arranging machine, valve inserting machine, nozzle pressing machine and capping machine. Functions can be enriched on demand.

| Outline of host (L*W*H) (mm) | 6800*1800*1900 |

|---|---|

| Height of aerosol can (mm) | 80-350 (customizable) |

| Diameter of aerosol can (mm) | 35-65 (customizable) |

| Closing diameter (mm) | 27.5 |

| Gas filling accuracy(mm): | 0.5% |

| Capacity (cans/hr) | 1800-2800 |

| Max gas consumption (L/min) | 3 |

| Working pressure (MPa) | 0.65-1 |

| Liquid fill (ml) | 50-1000 (customizable) |

| Gas fill (ml) | 20-500 (customizable) |

120B Automatic Aerosol Filling Machine for Pesticide Sprayer Production

The 120B series automatic aerosol filling line includs whole aerosol filling procedure: can arranging, inserting valve, filling and sealing in rotary table, weight checking, leakage detection(water bath), nozzle pressing, cover capping, text printing, carton sealing and strap packing.

All core components is Siemens and Schneider branded, the assembly line is a convenient & stable choice for many aerosol producers. No matter you are experienced or new to the aerosol business, this aerosol line will relase you from the production quality control and give entrepreneur more time to do the marketing job.

It's widely used and applicable to different liquid and gas, including water, oil, paint, foam cleaner, cosmetics... We can also offer filling solutions for medical meterial and food which will meet the hygiene and safety requiements.

| Outline of host (L*W*H) (mm) | 18000*1800*1900 |

|---|---|

| Height of aerosol can (mm) | 80-350 (customizable) |

| Diameter of aerosol can (mm) | 35-65 (customizable) |

| Closing diameter (mm) | 27.5 |

| Gas filling accuracy(mm): | 0.5% |

| Capacity (cans/hr) | 2000-3200 |

| Max gas consumption (L/min) | 5.5 |

| Working pressure (MPa) | 0.65-1 |

| Liquid fill (ml) | 50-1000 (customizable) |

| Gas fill (ml) | 20-700(customized) |