Application of aerosol pesticides and analysis of their filling equipment

How is the new tear sprayer produced?

September 26, 2019

Why bag on valve packing is superior to traditional aerosols

October 21, 2019Introduction of aerosol insecticides

Aerosol insecticide refers to the insecticide’s original solution filled with the ejector and sealed in a pressure tank with a valve, which sprays the insecticide in the form of fog when used. Aerosol insecticides have the advantages of good insecticidal effect, easy to carry, simple use and easy storage. With the continuous improvement of people’s living standards, household hygienic and insecticidal products have become the necessary daily necessities of most families.

The production process of aerosol insecticide filling

Pesticide raw materials are generally composed of low boiling point solvents and propellant gases. The main components of low boiling point solvents are low toxic pyrethroid pesticides. At present, the main varieties are allethrin, tetramethrin, propargyl, permethrin, and cypermethrin. Compressed gases such as nitrogen, carbon dioxide or nitrous oxide can be used as propellant gases. However, liquefied gases with a boiling point lower than room temperatures, such as trichloromethane, difluoromethane, and trichlorotetrafluoroethane, are mostly used in the market at present. The raw liquid is mixed by different chemicals and water according to a certain proportion of formulation. The purity of water and the mixing degree of stirring will affect the quality and effect of pesticide products.

Pesticide Packaging Materials

Aerosol or aerosol insecticide packaging materials are usually made of iron cans, valves, nozzles and large covers.

Aerosol Insecticide Packaging Material

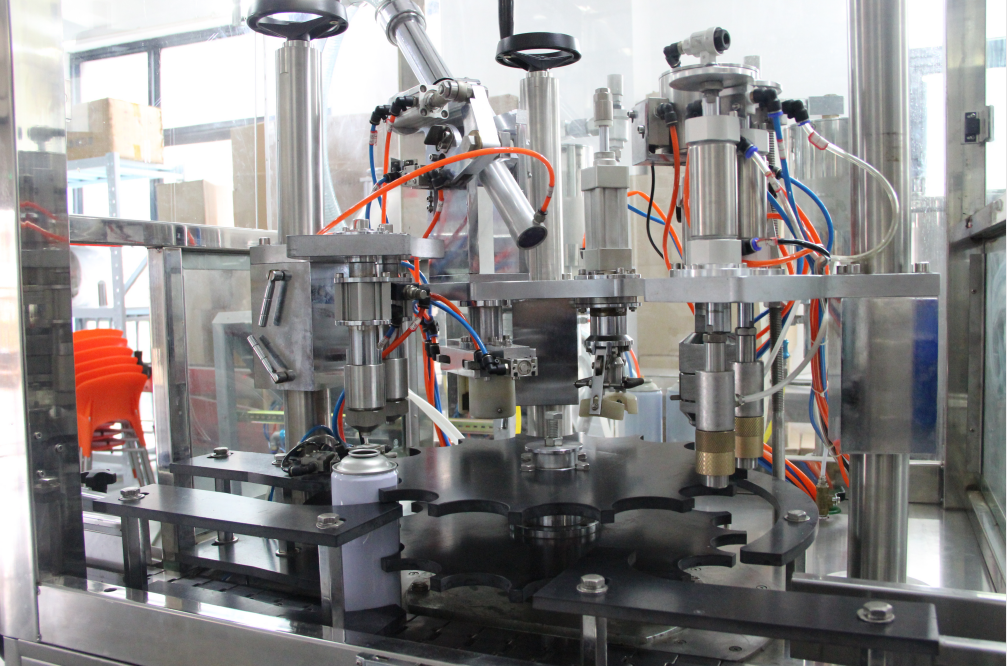

The production process of aerosol pesticides is generally as follows: production of raw liquid – > filling of raw liquid – > placing valve – > sealing – > aeration – > weighing – > water bath detection – > buckle nozzle – > top cover – > spray code – > packing and discharging from storage.

Selection of Filling Equipment for Aerosol Insecticides

For the selection of filling equipment for aerosol pesticides, we have a variety of filling equipment according to the different scale of the pesticide manufacturer, which can meet the needs of different customers.

1、For start-up enterprises, due to various risk factors, we suggest to choose the filling equipment: automatic aerosol filling equipment TK302; this equipment has many advantages, such as small floor area, simple operation, safe and reliable, fast filling speed, excellent performance, appropriate price, high automation, etc.

2、For large-scale production of pesticide manufacturers and customers, we strongly recommend the choice of automatic filling production line, such as automatic aerosol filling machine production line ; this equipment has the characteristics of the high-speed mass production line, great saving of manpower, safety and so on.

With the development of science and technology and the improvement of people’s living standards, more and more aerosol products will be produced, and the application fields will be expanded, and there are many potential areas to be developed. The equipment for producing such aerosol products includes semi-automatic production equipment of small enterprises and small-scale fully automatic equipment, as well as large-scale pipeline equipment with high production requirements. Wuhan Fitek supports customized equipment, plant layout, project implementation, all-round process support, one-stop nanny service.